How To Build Better Lapidary Equipment

This blog is based on my book of the same name. It is being written as a place for buyers of my book to connect with me.

Wednesday, May 2, 2018

Abrasion Theory And Application

Achieving a polish on stone is largely a product of our human vision, our ability, or inability, to see beyond a certain level of abrasion. After an initial PRIMARY abrasive application to most materials, these materials appear frosty, with a dull matte look. This is because the heavier, lower numbered silicon carbide abrasives (100-220), which are harder than most materials, visibly scratch the exterior of the rock (Abrasion). And because this scratching is relatively large sized, our eyes perceive the surface of the rock as being only somewhat uniform, giving it a frosty appearance. As the numbers of the polishing grits increase though, the size of the grit particles become smaller and smaller (As in so-many particles per cm) until we reach the final stages where the grits appear almost flour-like, very fine. Those abrasives work just as well, if not better than the heavier sized abrasives, once the heavier abrasives have begun constructing UNIFORMITY. The later grades of polishing abrasives make scratches so fine on a gems exterior that our eyes can no longer perceive the abrasions as scratches (That frosty look) and what we see is a smooth and shiny surface created by millions of tiny abrasions which allow light to travel more efficiently across or through the material of the stone. So. Polishing rox is a matter of Abrasion and Vision and Light. You are controlling, refining, the way Light effects a material, by altering its surface through uniformity (Smoothing the surface by gradually SCRATCHING it more finely) to allow Light better access, so that your eyes can no longer perceive the scratched look of the stone, for the watching of the Light! Many types of finishing on materials is called polishing, and that can basically be understood as “High Surface Uniformity”. Polishing is Abrasion. Machinery Parts, and the like, can easily be made more inherent, have higher synchronous capabilities, through polishing. Many abrasives are applied with water, although dry abrasion is very effective too in certain instances. Mixtures of wet and dry abrasion create their own interesting effects, and experimentation is yours. Experimentation is what its all about. Trix. Dry abrasion generates heat at a much higher rate, and this needs to be understood. A safety hazard is many times created during dry grinding or sanding, too. Airborne particles, inhalable. Remember that first and foremost. Fans work well to blow particles somewhere else, away from you, and dust masks are necessary if you get into dry abrasion at all.

How to Make Homemade Brass Bearings

These bearings are simple to make and work well for a long time. A piece of brass pipe is inserted tightly into a hole bored into a 4" x 4" x 4" block of hardwood. The bore into the hardwood is near the top, and a notch is cut across the block of hardwood intersecting the hole for the brass pipe. This is called the adjustment groove, in the diagram below. Another hole is drilled in the block 90 degrees from the brass pipe hole. This is a smaller hole and is used to accept a small bolt and nut, as a tightener once the brass pipe is inserted in the shaft hole. You can use a wingnut in place of the regular nut on this tightening bolt and it will make life easier. Oil the brass pipe regularly once the steel shafting, again, very tight fitting, is inserted into the brass pipe/bearing. The softer brass will conform quickly to the steel shaft once it is motorized and it will loosen up just right. Many manufactured brass bearings are used in lots of machinery worldwide to this day. If the brasspipe becomes loose in the hardwood block, just tighten the long bolt and nut to take up the slack.

Flat Laps for Lapidary Shops

Perhaps the easiest flat lap that can be built is from a double headed floor-scrubber machine that can be found in many thrift stores and flea markets. Almost total de-construction has to transpire, meaning you have to take it apart down to the motor level, while leaving the rotating heads in place. Then you must build a wooden or metal case for it so that both heads sit flat and will run freely when power is applied. It is best to incorporate plastic or wooden sidewalls to this box for safetys sake. No matter how hard you try, eventually a wheel will “Fling” a stone, and its better if it doesn’t fling it across the room.

Also, all wheels will throw an amount of abrasive due to centrifugal force, because water is usually mixed with said abrasive to create a slurry. See the section on abrasion and application at the end of this book for more information on that. To make good sidewalls for your flat lap, either build wooden edges all the way around the wheel, above the level of the wheel face, or cut the bottom out of a plastic pan or box, leaving enough of the bottom around the edges to use as bolt-down. Set the pan or box over the wheel, then screw down to whatever kind of baseboard you have constructed. Metal sidewalls are not advisable, because they may rust or be too sharp for safetys sake, and because if you throw a nice stone against it with force, as the wheel will often do, it will sometimes break the stone. Finally, plastic can be holed easily with heat, like a nail that has been heated up with a lighter. Hold the nail with pliers of course.

The floor-scrubber flat-lap wheels usually run counter to each other, as far as direction is concerned. One runs to the left, the other to the right. Not really a problem but something to be aware of. The nice thing about these floor scrubber flat laps is that the wheels/shafts are usually socketed and locked by means of a twist/pin system, meaning you set the wheel on the shaft according to the pin layout, then twist the wheel and it locks. Also, most times the wheels themselves can be had cheaply at any hardware, and no special equipment or mounting hardware is necessary to make this configuration efficient and profitable. Just remove the brushes, and screw on some plywood disks. Voila, theres the laps. On disks I always put a layer of neoprene rubber, divers wetsuit material, with the textured side up. To this I adhere my polishing pad or abrasive disk. Worx well. This lap can also be adapted/modified for faceting, most notably the jamb peg type of faceting.

The other type of flat lap which I use is almost as simple, and was put together in a couple of hours. Like my diamond saw, this flat lap makes use of a shaft bearing/spindle assembly from a rider lawnmower (see diagram above).

Instead of mounting vertically for a blade I mount this horizontally for a flat lap, Simple. Other parts for the project are a pulley belt, a motor, and some scrap lumber. I use a piece of plywood over a two-by-four frame to mount this flat lap configuration, with the two by fours on edge so there is about a 4” clearance from workbench surface to top of flat lap. This supplies clearance for the pulley and motor works underneath. I drill holes in the plywood to mount the bearing with the shaft pointing upward, and the pulley below the plywood. Then I mount the motor off to the side, with its pulleyed-shaft protruding BELOW the plywood table, lined up with the pulley. It may be necessary to put the motors shaft through a drilled hole, mount the motor permanent, THEN apply the pulley to the motors shaft below the top of the wooden frame box. I use a 1725 RPM heater motor and it was real easy to mount because it has a mounting plate on the front. I made the hole of one of these mounting screws elongated, so I could easily adjust the tension on the pulley belt by loosening that bolt, and pulling it tight. I cut out the bottom of a rectangular plastic box and fitted it over the protruding shaft of the lawnmower bearing, so that when my wheel was mounted on the shaft there was plenty of clearance but good high side walls. The nice thing about the lawnmower bearing is its shaft is usually threaded (Get one thats threaded!) and the mounting of the wooden or metal wheel only requires it to be center bored in the diameter of the shaft. Then the wood disk can easily be mounted with a couple washers on each side of the disk, and a nut that threads onto the shaft.

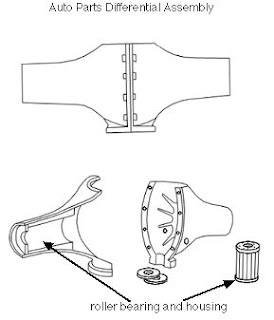

How To Build Bench Grinders From Car Parts And More

Piston Grinder

With a little alteration an old auto piston becomes a grinder head for light and small work. Cut the piston skirt off just below the wristpin bosses. A portion of the piston wall is then cut away creating access for a belt drive, or a hole drilled in the bottom of the piston could allow it to be driven from below. This diagram shows the rear-driven aspect. The shaft is turned to fit the wheels and threaded for retaining nuts. Collars should be turned at the same time the shaft is made, and should very closely conform to the diagram here. The pulley is a standard type available at hardware stores in 1" or 1&1/2" size depending on the size of the piston and the overall project. Steel pulleys are better than the white metal available as standard fare in the hardwares today. Drill small access holes in the shaft/bearing receptacles, so that these bearings can be oiled periodically. On this model all that is required are two small holes drilled through the base and it can then be screw mounted to any bench or plywood plate. It may be necessary to elevate the grinder with base plates to create clearance for the belt. Check everything before final assembly. This is a good little lapidary type grinder, but needs to be mounted in a pan and have a hood covering the wheel if you are going to use it to grind rocks. Lubricate the lapidary type wheels with a pressurized water feed or spray bottle of water. Finally, before the shaft is made check and see what type of diameters you will be working with as far as your particular abrasive wheels are concerned.

Please read this in its entirety before attempting to build. Safety First. Always wear eye protection when working with shop equipment. No warranty is implied or given concerning this information. The action of the author is to portray tested information. The action of anyone else, whether aware of this information or not, is in no way to be construed as actions of the author. This information is safe for anyone with good mechanical and electrical aptitude.

Sturdiness and accuracy come together in this inexpensive roller bearing grinder, which you can make from an old differential assembly. This grinder will handle wheels up to 12” diameter, and can be configured in numerous ways, including floor stands or bench models. Except for the machined shaft, which goes where the axle went, and the wheel collars, all the work can be accomplished with hand tools commonly found in any shop. Have the shaft custom machined at a machine shop unless you can do your own work with a metal lathe. I think top $ spent for this piece would be about $40.00, and probably as much as half that. If you can go to a schools machine shop and get them to do it for you, you will save substantially, and its a fairly easy job to perform. Metal stock can usually be obtained cheaply at scrap yards. Use the diagram here to show the machinist what you want, and furnish them the sizes for your particular salvaged differential assembly. The shaft should be cold rolled steel, around 24” in length, and 1&1/2” in diameter. Cast Iron disks known as building washers are your best bet for the four grinding-wheel collars you will need. Have them machined as they are diagramed, with a 1/16th" recess on the interior face, the face against the wheel. This is important to do. It is also very important to have the collar faces machined perfectly parallel, so the wheel rides true. The center bore of the collars must create a snug sliding fit over the ends of the shaft.

To make the drive pulley, four hardwood disks are bored to a Drive Fit (Tight) over a bushing made from a 3" length of brass tubing with an inside diameter of 1&1/2". The wall thickness of the brass bushing needs to be at least 1/8" thick. Use glue between the hardwood disks and clamp tightly until dry. When finished drill and tap through this wheel and the brass pipe for a headless set screw by which to affix the pulley to the drive shaft. A couple of set screws, one at either end, is optimum. Line 'em up.

Quite a lot of cutting and other modification is necessary on the housing, and different areas need to be addressed depending on which model you are making, either overhead or rear drive. Refer to the drawings for suggested ideas. The parts rests and wheel guards can be configured for your situation, and with a grinder of this size and power (2000 RPM Max) the parts-rest assembly is a very good idea, and the wheel guards a MUST. With the casing apart you will need to drill holes for the various accouterments to be attached, so it is a good idea to pre-mark your wheel guard assembly and part-rest assembly before you dissemble the differential housing. You will also need to drill for grease fittings tapped over the roller bearings themselves. Because the holes will be drilled at an angle it is best to drill smaller and then use a reamer to enlarge them. In order to tighten these assemblies bolts effectively, sleeves are cut from 1/2 inch pipe that fit over the bolts holding the assemblies on. The ends of these sleeves that butt up against the housing need to be beveled for a straight fit. The wheel guards are attached to the flat stock supporting bar at the back of the grinder, NOT at the housing of the grinder itself, so care must be taken with measurements and final fastenings.

When assembling the unit be careful to align the interior parts of the roller bearing assemblies correctly, and if you make notes as you take it apart that could be very helpful. You will of course be including all the new parts as you do it, so patience will be good coin for you here.

1800 RPM is the suggested speed of this grinder, with 100 rpm either way, and washing machine motors are 1725 RPM. A pulley on the motor the same size as the grinders interior drive pulley will rotate the grinding wheel at that speed. Smaller wheels can be run slightly faster.

If this grinder is to be used for lapidary uses, modify the wheel guard to except a water feed, and mount the unit in a water tight pan.

American Jam Peg Faceting

As in everything lapidary, the main aspect of jamb peg faceting is the grinding surface. All faceting units I have seen utilize a horizontal, tabletop type of surface. For many lapidary jobs this set up is good, but in faceting, especially when faceting jamb peg style, where working-by-eye is all important, the low horizontal surface restricts vision badly. I have overcome this by easily and efficiently creating a faceting/grinding surface perpendicular to that, ie. a Vertical grinding surface. This allows extremely fine viewing and does away with a lot of the calibration necessary in other systems of faceting. Your vision is optimized and you can begin to utilize it as your prime advantage, which is as it should be. Bill Gallaghers American Jamb Peg Faceting System is much easier to employ and master for making quality and valuable faceted gems.

Besides restricting vision when faceting, the horizontal grinding surface also causes some less natural postures than a vertical surface, as anyone who tries the latter will instantly see; among other things, a vertical grinding surface makes better use of gravity when holding a dop against the peg surface, and the attendant stone against the wheel.

My portable configuration, below, gets firmly C-clamped to a work table. I use a 1x2 spacer between the motor and the table to give clearance for the flat lap wheel and the bench, and I use a cut off clear 2litre bottle as a perfect sized wheel/splash guard. Position a section of the clear plastic bottle to cover the 6” lap wheel but not too much, just enough to keep from getting water everywhere. Do not restrict line of sight with the wheel guard. A 1725 rpm or LESS (Optimum maybe 1100RPM) electric motor sits on said 1x2 wood spacer, tack this plastic wheel guard to that spacer, ant gwon nowheres. If the sizes of your equipment varies from these measurements, adjust accordingly. This set up should be considered very elastic, and customizable to your needs. A permanently mounted configuration will generally help you make better work, but max flexibility runs a close second.

The bench mounted motor utilizes what is called a shaft arbor, or threaded shaft extension, they are made in 5/8” and 1/2” and even smaller. They fit on a larger motors shaft and fasten with set screws. These shaft arbors can be used to direct-drive wheels of many types. This direct drive is usually more integral than even multi-bearing shafts. Be aware of motor directions, and mount accordingly. You want the wheel moving INTO the work. Harbor freight has these fittings and many local hardware stores and rock shops have them too; you want to be able to mount a flat lap sidewise (VERTICALLY), washers either side, tightened down, immovable while operating, but easily removable because there are multiple grinding steps. This vertical grinding surface is a primary innovation. It can be employed for faceting in many ways, and is very well suited for jamb pegging.

The second most important aspect of the jamb peg system is/are the dop stick(s). These must be uniform to a fault, due to the fact that their length and makeup are used continually and interchangeably with a notched board or other like surface type (The peg surface, think of a cribbage board) so that angles of facets are easily repeatable and will tend NOT to overcut. That is the nature and advantage of the jamb peg system, in a nutshell. I use bicycle spokes clipped in various but uniform sizes, 4" 6" 8" and these 3 different sizes come in handy for larger and smaller stones. For some operations (Depending on the make up of your peg surface) sharpening of the end of the dop will aid you well. The aforementioned salvaged bicycle spokes utilize the rim end as the dop end, it is even shaped for it, and the tool notch aids adhesion. These spokes as salvage are free or thereabouts. If they are too thin to hold safely, find larger diameter spokes, or drill a dowel and make a holder for yourself, so the end of the spoke protrudes and can be jammed in the peg surface, but you also have a handle. The cut off bike spokes are especially well sized for small fractional-carat stones, and because of the vertical grinding surface of this system are really a fine tuned aspect of it. Other dop systems can be used, even wax and wood, and a lot of what is conventional for jamb peggers will work as far as dopping goes.

The third and final part of any jamb peg system is the peg surface. This is where the end of your dop is pushed into or against. Some of the jamb peg systems utilizing a horizontal grinding surface use actual peg boards mounted 90 degrees to a table or other platform, and some even use a head affair, cylindrical, curved, and there are even other more esoteric peg surface configs I am sure. To use any of those systems, constant downward pressure must be applied to keep the dop stick jammed into the peg surface as the wheel spins INTO it. The action of the wheel as it spins toward both the work, and the peg surface, has both a pushing back on the dop and pulling down on the stone effect, to a certain degree, but with a vertical grinding surface (lap turned/mounted on edge 90 degrees to horizontal) all that is needed is sidewise motion to cause the wheel to push the dop down into the peg surface, which is mounted to the bench top.

Once again, because of the vertical grinding surface our faceting tools become more useful and simpler at the same time. Because our sight is so much greater in this configuration, and because we have gravity on our side, the peg surface can now be varied and utilized to much greater degree as well. Instead of an actual cribbage board type peg surface which is mounted on the bench in relation to the vertical grinding surface, consider disposable peg surfaces like leather or medium hard plastix. The patterns you make with a pointed dop end as you facet a stone are sure to tell you a story afterwards as well. Be astute.

Steps in faceting: cut the preform from the rough, grind the preform into shape, dop the preform stone with short term epoxy (2-5 minute set - Need acetone soak to remove). The top and the bottom of a faceted crystal are accomplished in two separate steps. Many cut and polish the crown/top/bezel part first. When cutting/grinding before the polish, leave room for loss of material during later steps. That judging of material as you go is the real art of faceting. Practice on hodads before getting antsy with good stuff.

Once the crown/top is finished, transfer the stone from one dop to another, without losing any orientation, by using a transfer block. Below is an illustration of one, it uses set screws and channels to hold the dops while epoxy is being applied or removed. One or both sides slide to make room for the operation with two stix/spoxe. Precision is everything here, and thats another good reason for the bicycle spoke dop stix, they are uniform. You must develop a system of dopping that works well for you, with no variance at all during the transfer. Study well. Net. Library. Rock Clubs.

Cut and polish the bottom (Pavilion, Back, Base) in equal facets according to Eye Appeal and your studies of various cuts and gemstones.

The set up for jamb peg faceting can be as simple as is diagramed here, which is to say portable, or it can be made semi-permanent or permanent, depending on your situation and what you want. This will get you faceting quickly and well, with a distinct knowledge advantage. Experiment with various grits, many times a worn 100 lap will be like a 220 or 360, and so on. In my other lapidary pursuits, abrasives for various stones are almost like recipes, although for crystal one can be assured of a fine finish with diamond, climbing the scale from very heavy to very fine, in as many steps as one can afford.

Safety is important, and I recommend (In this order) wheel guards, safety glasses, patience, and distaste for pain. You will be ok then. No helmet required.

Please do research faceting further, faceting patterns, and other literature. Faceted stones have not been around too long and even some relatively modern stones are just a crystal cleaned up. For the best short history of faceting I must quote Barbara Smigler (Find her free gemology course online, you will be glad you did):

“...Several hundred years ago the jamb peg faceting machine came into use, and faceting, as we recognize it today, began. In order to cut facets on a gem in an organized manner that results in a precise arrangement, three factors must be controlled: 1) the angle of the cut 2) the depth of the cut and 3) the radial placement of the cut. Although modern highly engineered faceting machines have replaced jamb pegs in much of the world, these older systems are still widely used, and a substantial proportion of the gems in commerce today have been cut by them...”

Yes.

There is a plethora of information online and at most libraries. Write luxefaire@gmail.com with questions.

Remember above all that even if you can afford a machine with all the bells and whistles you will be seeking the same end product as a jamb pegger, a bright beautiful stone, and eventually, after enough time and practice has passed, you will be handling your machine like a jamb pegger too, by feel, and with an expert eye.

This system (Vertical grinding surface/bench top peg surface) has the exact same action between grinding surface and stone as the conventional configurations, but is now more amenable to human manipulation and sight.

Finally, I am sure that a lot of this type of thing has been done before, its just that I have only seen horizontally mounted machines and methods, and this change of method works much better for me.

BG

Build A Giant Rock Saw

You can build a giant slab saw for monument and masonry work out of easily acquired parts and materials. Many of the parts and materials can be salvaged: junked lawnmowers, washing machines and dryers, the list is long and even some car parts lend themselves to building custom machine tools like mudsaws and other stuff. For this project you will need a piece of steel bar, some pillow block bearings with attendant shaft stock, scrap lumber, and a few nuts, bolts, and screws. Threaded rod is good stuff also, and comes in very handy during this project as well as others. And you will need a standard 1725 RPM washing machine/dryer motor, 1/4 or 1/3 horsepower.

The blade of this machine is a steel bar of the type used in spring suspensions of vehicles. The steel is about 1/4 inch thick, and about two or three inches wide. The length must be determined by you, but around 36" is good enough to get some fairly large sized cuts. The actual weight of this blade facilitates the cutting of the rock, as abrasive is fed to it while it moves back and forth in a reciprocating motion. It is not a speed machine by any means, and should only be used in its presently explained config for softer materials like onyx, sandstone etc.. Greater efficiency can be had, but at a price. Weighting the blade can add to speed, but lugs the motor. The next mud saw I build will be chain driven by a gas motor, like a lawnmower motor. Then a lot of weight on the blade will not be a problem and it will cut a lot faster than an electric motor can. Overall, this project is worthwhile if you can employ it, because large diamond saws run into the hundreds of thousands of dollars. If you can accomplish the same thing, albeit more slowly, for a hundred bux or less (A LOT LESS!), that is an advantage par excellence, and the extra time taken becomes a minor problem. Steady does it with this saw, and as long as your mechanical set up is durable, and the abrasive/water feed runs properly, you can do some amazing things with a mudsaw, not least of which is to make some major dollars. Tiles and building stone of odd materials bring really good money.

Once you get the hang of using your mudsaw, you will discover all sorts of methods and trix to make your life easier, and make your work more productive. Stonework is one of the very oldest arts, and the selection of stoneworkers tools is extensive: chisels, drills, snips, hammers; all can be used to good effect. Find a book called STEREOTOMY and read it. After this book of course. You will be glad you did. Right now I will give you the basic idea, which then should be modified to your particular needs.

Like any lapidary equipment, the SLIDING BAR saw, or Mud Saw, works through abrasion. Its because of this that it is called a mudsaw. The abrasion process creates a lot of ground up rock which gets mixed with the abrasive slurry, and the end product of the cutting can only be called mud. You will of course want to restrict use of the mudsaw to the outdoors. It really comes in handy in the GREAT outdoors, like when you find an outcrop of stone where you can leave your saw, and cut on site. The steel bar of your mudsaw is just the carrier and weight for the abrasive, which is generally silicon carbide grit, in about 80 to 100 size. Quartz or garnet sands work on softer materials as well. Two things you have to get right on this saw, are the blade guides, and the drip feed. A few ideas are given here, and it pays to experiment around somewhat, once you get your saw done, to see what worx best for you.

The first order of business in getting a mudsaw up and running is to build a mechanical step down of the motors speed, so that it decreases the usable speed of the 1725 RPM to about ten percent or so of the actual motor speed. You will want a very small pulley on the motor shaft, and 2 very large pulleys afterwards. Optimum speed for the mud saw is 25 reciprocations per minute. You will have to experiment, and that can go up or down a little (RPMs) and still work fine. Say between 20 RPM and 35 RPM, with lower speeds being better. Sometimes you can get small heavy duty high-torque low-speed motors like are used on hospital beds, and do away with a lot of the rigmarole of building a step down set-up. Here is the step down unit I used first, and it worked fine, and was not too hard to build.

You will attach the stepped down motor power to a disk of heavy plywood, and bolt the bar blade to it in a bearing type arrangement, so as the disk turns, the blade moves back and forth. Diagrams here are a must, and explain it better than I could in many words:

How To Build A Home Made Diamond Saw

Building a diamond saw for cutting rocks is very easy and inexpensive. With a washing machine motor (115VAC, 1725 RPM) and a few salvaged parts, you can make a saw that will handle from 6” blades up to 10” blades, without a problem. These plans can be adapted and modified even further, to incorporate larger blades and capabilities. Here is all the information you need to get into lapidary work on a professional basis, or to upgrade your shop, for pennies on the dollar.

You will need a base for your machine, and I recommend 3/4 inch plywood of marine quality if possible. Other types of plywood work fine, although eventually moisture will get the wood, causing it to weaken and rot, and there is a lot of moisture in lapidary work. A good coat of heavy oil-based paint on both sides of regular plywood, and along the edges, will waterproof well too. Even cheap plywood uncoated will many times go for years, so do not go out of your way to buy a sheet of marine plywood for this project, because that would be purposeless and expensive. Once you realize how easy it is to build equipment for yourself, you will probably replace your first saw with a better one before even the crummiest plywood would go away. Try to salvage the wood you need, and everything else. Its fun, like a treasure hunt, and everyone knows there is a plethora of junk lying around all over the planet, and maybe by building stuff out of it we will actually do the planet a service. Wouldn’t that be nice? I'm sure.

Always talk up salvage possibilities, make friends at boatyards and construction areas, thrift stores and dumps. You will be glad you did. The most important part about the plywood is the thickness; it must be stout. 3/4” is good. It should be on the order of 24” by 24”, and if you like you can assemble all your parts, then lay them out as they will fit on this plywood base, then the plywood can be trimmed to the size and shape that will work best.

The next thing you will need is a housing for the saw itself. Because the lubricant for diamond tooling is water, this housing needs to be waterproof, and it is good if a pluggable drain is incorporated at trddddd3rhe bottom of this housing, whether through aquarium fixtures, small plumbing or auto parts---it doesn't matter, but a drain will make life a LOT easier down the road. The housing should be metal, and as strong as possible without overdoing it. You Don't need 1/4" steel for this.

It is also possible to construct a wooden housing as a form for fiberglass resin and cloth, but that is excess effort for most people, and not as strong or easy to obtain as a metal box. The metal of the box must be sturdy enough to handle the force of a large motor-run bearing, but should also be workable with hand tools, like hacksaws, hand drills, and the like. Some fixture boxes used in the electrical industry lend themselves well to saw applications, but besides those pre-made terminal boxes made to hold electrical wiring, the best and RECOMMENDED housing for your saw is an ammunition box, of metal, that can be obtained from army surplus stores. They measure small, medium, large, for the most part, with the smaller being around 6” wide by 12” long by 8” deep. Some of the larger ones are truly gargantuan, and only good for making really big saws, like ones that hold 24”+ blades. The small ones, good for 6” or 10” saws, run anywhere from $5 to 10.00 apiece, but look around, you may just find one languishing somewhere.

To test a metal housing for leaks with your vision, hold the box up to the sunlight, looking into it, and see what you see. Light shining through anywhere within the bottom part of the box means leaks, and leaks are bad. Remember to judge the size of the housing-box you obtain by using a blade as a measuring guide. If you don’t have a blade cut one out of cardboard, 6” or 10” across the circle. You are going to want nearly one half of the blade protruding above the cutting table, so its important to judge the size of the box correctly, and position the blade correctly in reference to the box.

This pertains to the bearing assembly, as well, which the blade is affixed to. You want the blade to come within 2” of the BOTTOM of the housing box (The closer to the bottom of the box the better) without sacrificing blade height on the cutting table. This is because the lower the blade sits in the box, the less water you will have to add to the box to get the blade continuously running through it. And thats why the box must needs be waterproof, because it is going to hold the water which the blade HAS to run through in order to keep it cool, and to lubricate the steel/diamond composition on its edge.

Once you have your base and housing, the next part you will need, and perhaps the most critical of all the parts in this project, is a salvage item that can be had at any used lawnmower shop. They can be purchased new or used, and many times the used parts are just given away. These marvels of technology are called a "Spindle Assembly", and are the actual bearings used on lawnmowers which the lawnmower blade is attached to. I have been given many, free, just for the pulling. When pulling them make sure there is little or no play in the bearing, and pull them from the HOUSINGS of Front-Cutting Rider Lawnmowers, if at all possible. Most rider lawnmowers do not have direct drive from the motor to the blade, but a transmission and series of pulleys which redirects the rotational energy from the motor to the blades. Many times on these rigs there will also be a permanent pulley attached to the stationary shaft (Spindle) running through the bearing (A NICE THING!) and occasionally you get to salvage a few belts as well as the bearing/spindle assembly. Good pre-work inspection of the bearing is a MUST, because there is a gnarly bit of work involved in getting the spindle assemblies loose, not least of which is removal of the lawnmowing blade. Once the blade is off there are some bolts and nuts where the mounting plate of the bearing is bolted to the blade housing, so bring some adjustable wrenches of several sizes, a couple screwdrivers, maybe a chisel, a hammer, and some gloves with you to get the parts. I like vise-grips and liquid-wrench-in-a-can a lot too. They always come in handy. Do not damage a good bearing in removal. Get all the fastening hardware off, and the blade, and if it is frozen on the hood/housing strike the bearings mounting plate lightly with hammer and chisel to break loose the assembly from the rust or grime or both holding it in place. Save ALL the hardware from this operation, whether you think you will need it or not. If you throw it away you WILL need it. Most especially, save the mounting hardware that holds the blade onto the spindle shaft. There may be a couple nuts, washers, a bolt running down the center of the spindle, etc., etc..

Here is a diagram of the Lawnmower Bearing/Spindle Assembly as viewed from the side, with the lower grooved portion representing the pulley:

It is very important to get this basic type of pulley bearing/spindle assembly. The whole construction of the diamond saw revolves around this. It is an advantage employed whereby one type of equipment is introduced into an area it was not necessarily created for, but achieves greater efficiency than present art. These are the type of advantages everyone can use, and the possibilities are limitless. For now just be glad this is available so that you can make a BETTER diamond saw than can be bought on the market, for a lot cheaper price. Later you can think of other ways to employ this spindle-assembly bearing set up to your advantage, and there is even another machine in this book which relies on the advantage of the stationary-shaft lawnmower bearing/spindle assembly.

Finally, you can buy a new spindle assembly to suit your needs, and STILL save a lot of money in constructing a diamond saw, but that means you are going to have to part with a good little chunk of dough, and also deal with the guy at the counter. Your choice. I myself prefer the lawnmower graveyard and only the birds tweet-tweet-tweeting as my wrenches rattle and dance.

MOTORS

Now, a word or two about motors, because they are all important, and because this is the first chapter of this book. In order to avoid redundancy, we shall get it it over with right here. The very best motors for lapidary work are the older, heavy duty, cast-iron encased Alternating Current (AC)1725 RPM (Rotations Per Minute) motors from a variety of equipment. I say the older ones are better because they were made better, beefier, more heavy duty, last a lot longer. But even the 1725 motors made today have to possess a certain sturdiness, because of their applications, and they are most commonly found in washing machines and clothes dryers.

When a washing machine or dryer breaks, it is usually NOT the motor. It is usually a weak point in design or workmanship within the mechanical automata of the machine, which govern the feeds, draining, agitation, and so on of the machine. A lot of the older washer and dryer machines are junked because its time to upgrade anyway, or its easier or less expensive (Than repair) to buy a new one, so these motors are ALWAYS available. You can buy them at fleamarkets sometimes, pulled, for as little as 5.00 each. New motors of the same type cost a couple hundred or so. Use an electric cord with a plug on one end and bare wires on the other to test motors. Hook the bare wires to the wires of the motor, twist on some wire nuts, or electrical tape, and plug it in. Make sure to keep any bare wire from these two connections from touching each other, or you will see some sparks. If the motors windings are shorted it might fizzle and smoke a little bit, but hardly ever does that happen; usually a capacitor goes bad and the older motors don’t even use capacitors for starting up, which is another reason the old ones are desirable.

If the capacitor on a newer motor is shot, the motor will likely just sit there once power is applied. Many times there are more than two wires coming from the motor itself, and it pays to test some of the various combinations by applying ac current with your cord to them, because sometimes different connections create different speeds within the motor. You cannot mess up polaritys testing these motors because they utilize Alternating Current, which means the current alternates from positive to negative continuously as it moves sideways through time/space, and in the case of America, at 60 times a second! Thanks Nikola Tesla! You are not forgotten! When obtaining AC motors to build machines, always try to remember how you are laying the machine out, and what mounting configurations will be easiest, strongest; most advantageous. There are many different configurations of motor mounts, just remember that if you do not get a motor with a mount on it, you will have to mount it in ways that take a lot more time and effort. Once the motor is tested, do not forget to mark the direction the shaft turns. Put it somewhere easy to see, and make it indelible.

Onward. Once you have obtained the most necessary four parts -- wooden base, housing box, electric motor, and bearing assembly, all you will need is a pulley and and a pulley belt, some woodscrews and metal screws, a few nuts and bolts, and some strips of galvanized metal such as flashing from a roof job. Also line up a small plastic serving tray like you see in some restaurants, and some thicker sheet plastic such as 1/8” lexan or acrylic or even nylon if its around. Plastic is EVERYWHERE, so you should not have any trouble finding it. The other stuff can be salvaged or purchased cheaply. And of course you will need a diamond blade too. See the suppliers list at the back of the book for information concerning where to get the best deal on quality diamond tooling.

You will want the speed of your diamond blade a little less than 1725 RPM, around 1500 RPM, so make sure the pulley you get for the motor shaft, which DRIVES the belt/bearing/blade, is slightly smaller than the pulley on the spindle/bearing assembly. Of course if you wanted to speed the blade up you would do exactly the opposite, the pulley at the motor would be Larger than the pulley at the load. This is how you adjust machine speeds by varying sizes of pulleys.

The speed of the blade does not have to be exact, so don’t sweat over it, 1500-1800 will do the job well, but the faster it goes, the more water it will sling, and the greater the damage when a rock jams in the blade.

Assembling The Saw

Now we put it together. As stated above, the optimum situation is where you assemble all the parts first, before trying to assemble the machine. This way you can lay it all out in very close resemblance to the way it will look when its done, and make any necessary adjustments while it is easy to do. Believe me. I learned this the very hardest way possible, and though there are advantages to freeform assembly if you are into design and engineering heavily (Sometimes Mistakes Work Good!!), the learning process dictates that durability and efficiency are based on a firm foundation in construction. That fancy little bit of wording there simply means IF YOU DO NOT SET IT ALL UP FIRST, BEFORE FASTENING BEGINS, YOU’LL BE SORRY. Rasta say: “Measure Twice, Cut Once”. Thats Good Advice.

Lay out the parts, and configure them so the pulleys of the bearing and the motor line up. The motor goes behind the housing box. And the blade needs to turn TOWARD you. You may have to flop the motors position around to get that right, but it is VERY IMPORTANT. Mark your board by outlining the pre-positioned parts, and get to work on mounting the lawnmower bearing on the housing box.

This is probably the hardest part, other than obtaining the lawnmower bearing. Its pretty much up to you how the blade housing box is mounted to your wooden board platform, just remember punctures are not good, and should be minimized. The housing box can be strapped to the board with good effect (See diagram below), or certain waterproof fasteners are available where you drill the bottom of the box and the screws tighten up a rubber grommet sealing the surfaces. Unless you are familiar with that type of fastening, I do not recommend it. When strapping the box to the wood, remember to keep any holes well above the future waterline of the box. That means about 3 inches above where the bottom of the blade will be, at least.

To mount the spindle assembly you are going to have to cut the housing box to fit whatever type of bearing you have. The bearings have a plate with bolt holes already pierced there, from where it was mounted on the lawnmower housing. You will want to utilize this of course, so keeping in mind the future water level of the box, as well as maximum clearance of the blade at the top edge of the box, position the bearing on the side of the housing box EXACTLY where it should go, and mark it. Do not let any part of the bearing or its pulley protrude ABOVE the edge of the box, because that will eventually be the base for your saw table, and it needs stay level. When I use an ammo box, I drill two holes in the side of the box, then cut down to those holes, bend the flap over, and use it to secure the box to the wood base. There are many different ways of doing it, but if you can make that happen for you, it will save a lot of time. See diagrams below.

If the bearing HAS to protrude for some reason above the edge of the box, said edge can be built up later by fastening one by twos around the edge, or what have you, so don’t get bent out of shape if that happens. ANYTHING CAN BE FIXED!! But fixing takes time, effort, and materials. I am trying to save you as much as possible concerning all that. Keep going, you will be cutting rocks in no time now.

As far as cutting the box goes, drilled holes will aid your layout of the cuts and just make life a lot easier all the way around. I usually hacksaw through the boxes side down to the holes. It is tedious but works and is pretty quick. Sawzall would work real well too.

If there is a grease fitting on the bearing from the lawnmower, position it before you mount the bearing, so you can easily grease it later. If there are any voids between the bearing and the housing when it is placed, you will either have to make a gasket for it, or caulk it with silicone before using the saw, else water will find its way out even the tiniest of holes.

Once the box is punctured correctly, and the bearing is mounted, mount the box to your board, attach the pulley belt to the motor and bearing, and mount the motor to the board. Keep the pulley belt as tight as possible during this operation, because it will loosen with time and wear anyway. You can actually place the pulley belt AFTER the motor is mounted, by putting it on one pulley, then getting it started on the other pulley, and turning it so it presses itself on. Measure twice, and then mount the motor and pulley belt. You are now very close to finishing this project!

Mount the blade on the bearing. This is where some custom work will probably come in, because each bearing is a little different. Use whatever combinations of nuts bolts washer etc on the shaft of the bearing to make the blade secure and running true. Over tightening sometimes warps blades so do not. Blades have different sized shaft (Arbor) holes, so you may even have to make or purchase a bushing. Most lawnmower bearings have a center bored shaft with a bolt...this is good, it makes your mounting project simply a matter of washers and bushings. Washers touching the blade should be as large as possible but fit the shaft bolt exactly. Any others used to space or shim can be smaller, but the two washers touching the blade must be uniform and at least an inch and a half across, or thereabouts. The diagram above will help you with this also.

Now make a cutting table from a raised-edge plastic serving tray and some plastic sheet. Use the mounted blade in the box to measure where you need to cut a slit in the serving tray JUST large enough for the blade to protrude through. Only make it as long and wide as it HAS to be, otherwise more water gets slung about. See diagrams.

You can either make the table socket to the box by attaching a lip underneath, or you can fasten by screwing the table itself to wooden fastening points attached to the side of the metal box for that purpose. Build good splash guards that do not restrict vision but keep most of the water in the saw. Gravity feeds and holding vises can be made for this machine, and it can be modified for larger applications with ease.

Subscribe to:

Posts (Atom)